Good Quality, Faster Services, Best price

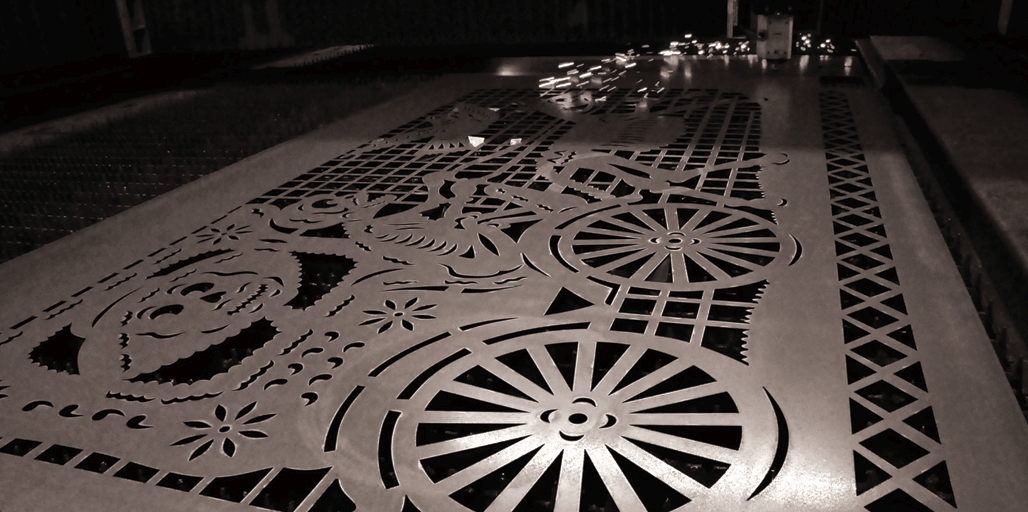

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser, by computer, at the material to be cut. The material then melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications. Laser cutting works by directing the output of a high-power laser, by computer, at the material to be cut. The material then melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

CNC laser cutting offers low cost for prototype and short runs

Laser cutting can produce almost any 2D shape. Laser cutting can produce parts such as enclosures, cams, brackets, sculptures, holders, mechanisms, etc. CNC laser cutting can be applied to several types of materials. Milled Steel, Stainless steel, and Aluminum, are highly suitable for laser cutting. Acrylic is an excellent material for laser cutting and results in a near polished edge. Laser cutting Metals such as copper alloys are difficult due to their ability to reflect the laser light and absorb heat. Laser cutting many plastics are problematic due to toxic fumes.

Our Laser Cutting Capabilities:

- Cutting up to 0.5″ (12.7mm) Steel

- Cutting up to 0.25″ (6.4mm) Stainless Steel

- Cutting up to 0.187″ (4.76mm) Aluminum

- Cutting as Thin as 0.008″ Steel and Stainless Steel

- Cutting Envelope is 80″ x 164″ (cm)

- Excellent Edge Quality for Aluminum, Steel and Stainless Steel

TECHNOLOGIES – Benefits

Lasers benefit engineering applications because of their monochromatic, directional and coherent characteristics. Being able to control a broad range of laser parameters precisely is what allows mechanical engineers to use lasers for manufacturing processes. Laser cutting is precise, clean and silent.

A laser beam can be focused on an extremely small area from 0.1 to 1mm in diameter. Because of the ability to focus a laser beam that can equal a million Watts per cm2, the incident laser beam causes a type of superficial fusion that triggers the cutting process in nearly all metals, in spite of the high levels of surface reflectivity.

By using laser technology you will be able to create parts quickly and cost effectively. There are no tooling requirements due to the fact that you simply program the computer and the Laser is able to accurately cut and reproduce the design over and over again. Unlike water and traditional cutting systems a laser beam exerts no mechanical or outside contact on the piece being cut.

Advantages of laser cutting over mechanical cutting include easier work holding and reduced contamination of work piece (since there is no cutting edge which can become contaminated by the material or contaminate the material). Precision may be better, since the laser beam does not wear during the process. There is also a reduced chance of warping the material that is being cut, as laser systems have a small heat-affected zone. Some materials are also very difficult or impossible to cut by more traditional means.

With our lasers and a continuous operating capacity, Laser AMP is able to adapt to different production volumes, cutting a variety of metals, namely: steel, stainless steel or aluminum.

With regards to the characteristics of your specialized project, we will tailor our services to address your specific needs. Whether your parts are 1 inch thick or 28 feet long, our array of equipment helps us meet your specific demands, quickly and accurately.

Capacities

- Steel: 1 in.

- Stainless steel: 1 in.

- Aluminum: 5/8 in.

Specifics

Our cutting table can accommodate metal parts up to 28 feet long.

A strong presence in the industry

Industries & Applications

Here are the primary industries we work in:

- Road and railroad transportation;

- Heavy equipment and construction equipment;

- Industrial machinery;

- Furniture industry;

- Electric enclosures and electronic modules;

- Energy;

- Water treatment.

Precision Cutting Material Capability

| Material | Thickness |

|---|---|

| ** Titanium, Inconel, Hastalloy, Brass, Galvanized, Silicon Steel, Tool Steel, Aircraft and other exotic material. | |

| Low Carbon | .004” to .750” |

| High Carbon | .004” to .500” |

| HSLA | .004” to .750” |

| Stainless | .004” to .500” |

| Aluminum | .004” to .312” |

| Spring Steel | .004” to .500” |

| Plastic | .004” to 1.000” |

| Rubber | .004” to 1.000” |